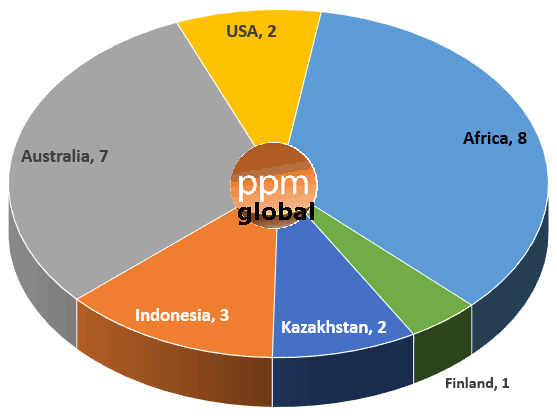

PPM Project Map

Move your mouse cursor over a project pin to view more details

-

- Project: MUMI

- Location: Kolwezi, Democratic Republic of Congo

- Scope: Commissioning, process optimisation and operator training

- Process: Copper Leach / SX / EW

- Client: Mutanda Mining

- Project: Kamoto Phase 4

- Location: Kolwezi, Democratic Republic of Congo

- Scope: Commissioning management

- Process: Copper Leach / SX / EW

- Client: Katanga Mining

-

- Project: Wetar

- Location: Wetar Island, West Timor

- Scope: Construction supervision, commissioning and operator training

- Process: Copper Heap Leach / SX / EW

- Client: Finders Resources

- Project: Wetar Copper-Gold mine Stage 2

- Location: Indonesia

- Scope: Commissioning and Operational ramp up, including operator training

- Process: SX EW 25,000 tpa upgrade (heapleach)

- Client: Finders Resources

-

- Project: Lady Annie Operation

- Location: Mt Isa, Queensland

- Scope: Commissioning and operator training

- Process: Copper Heap Leach / SX / EW

- Client: CST Minerals

- Project: Leichhardt Operation

- Location: Cloncurry, Queensland

- Scope: Commissioning and operator training

- Process: Copper Heap Leach / SX / EW

- Client: Matrix Metals