What is Heap Leaching?

PPM Global’s heap leach support services have improved mineral extraction efficiencies, of heap leach or leach pad projects around the world.

A leach pad is defined as a continuously lined area which may contain one or more ‘heaps’.

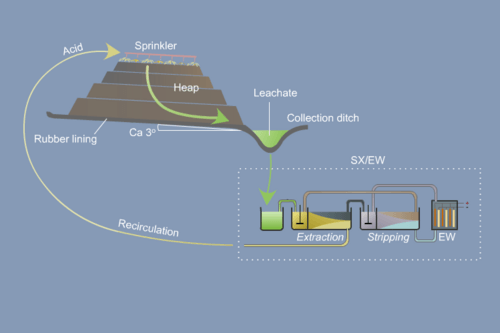

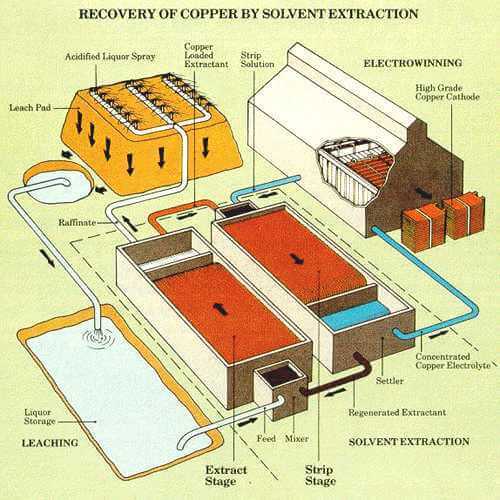

Leach Heaps (Cells) are stacked on prepared pads to a height from 4m to 8m high. The nominal heap leach height is 6 metres. The heaps can be approximately 50-60m wide. Heaps may contain between 50,000t and 250,000t of ore each. Heap leach solution is irrigated over the ore and percolates by gravity through the ore. The solution is collected at the base of the leach pad in a collection drainage system. While the solution (eg acid) passes through the ore, various metal ions are dissolved in solution. Eg copper (Cu), in a copper-bearing deposit. Copper is dissolved from the ore into the passing leach solution (Leachate). The primary chemical in the leach solution is sulphuric acid (H2SO4). The copper (Cu) is solubilised (dissolved into solution) according to the following simplified reaction: